Tubular Ceramic Membranes: Aqueous Italy's Advanced Filtration Solution

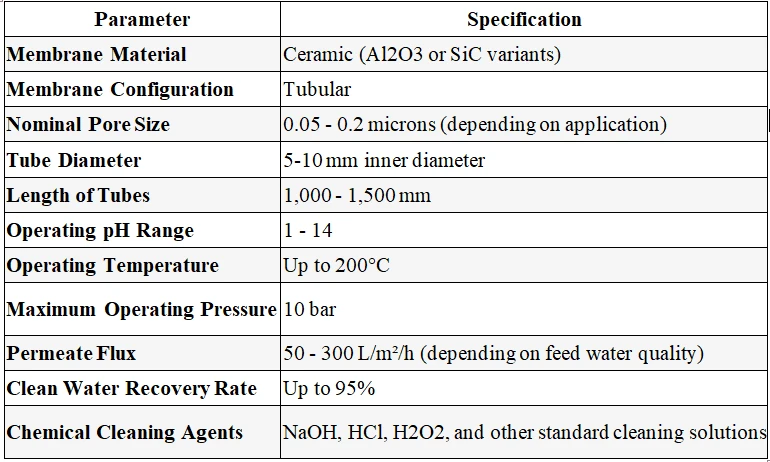

Tubular ceramic membranes by Aqueous Italy are engineered for high-efficiency filtration in demanding water and wastewater treatment environments. Built with a robust ceramic structure, these membranes deliver exceptional mechanical strength, chemical resistance, and thermal stability, ensuring consistent performance even under harsh operating conditions.

With long operational life, low maintenance requirements, and superior contaminant removal, Aqueous Italy’s tubular membranes provide a reliable, cost-effective solution for municipalities and industries seeking sustainable water reuse, safe discharge, and dependable filtration performance.