Design Philosophy

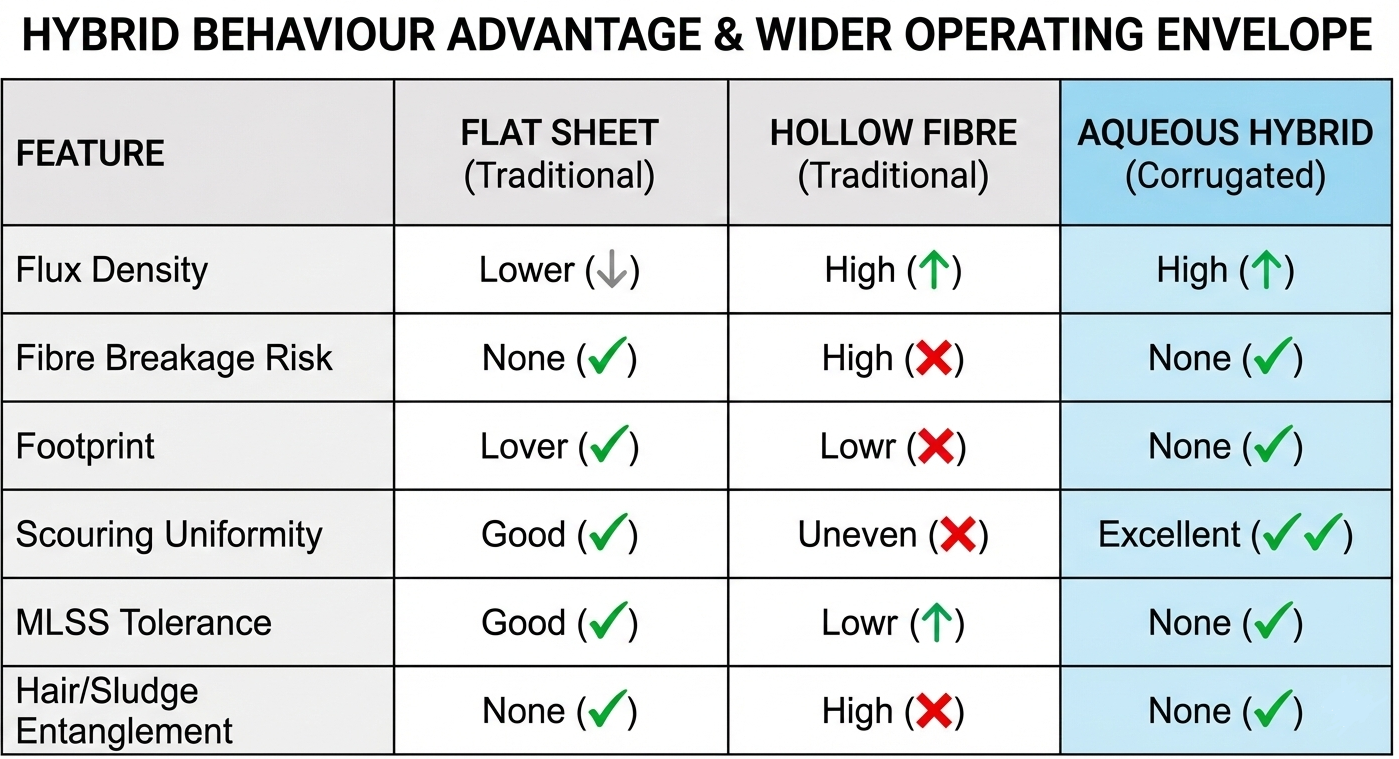

Aqueous Italia hybrid flat sheet membranes feature a corrugated, edge-potted construction, intentionally engineered to merge the hydraulic efficiency of hollow fibre membranes with the mechanical robustness and serviceability of flat sheet formats. The corrugated geometry is not cosmetic—it is a functional hydraulic structure designed to improve flux stability, fouling resistance, and mechanical integrity under submerged MBR operating conditions.

With long operational life, low maintenance requirements, and superior contaminant removal, Aqueous Italy’s tubular membranes provide a reliable, cost-effective solution for municipalities and industries seeking sustainable water reuse, safe discharge, and dependable filtration performance.